Dimensional weight is one of the most important factors in the pricing of shipments – and – one of the least understood factors. Also referred to as DIM weight, it has such an impact on your shipping costs that improperly calculating it can lead to lost revenue if not calculated correctly.

What is Dimensional Weight?

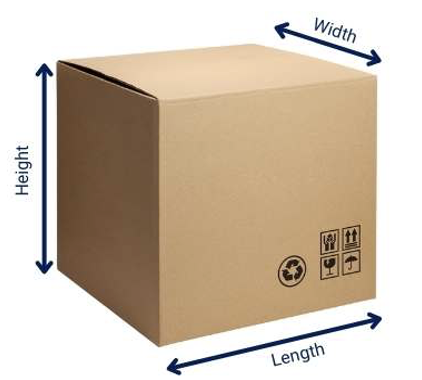

Dim weight is a pricing technique that refers to the volumetric weight of a package. So, it really is not a “weight” but a volume metric.

Dim weight = (length x width x height)/dim weight Divisor

It’s a simple formula that calculates the amount of space in weight a package occupies. It is universally used by logistics and supply chain companies including carriers like FedEx, UPS, USPS, and DHL.

DIM Factor (aka DIM Divisor)

Carriers have limited space on trucks. In order to maximize the space and adequately price packages, each carrier will establish a DIM Factor or DIM Divisor. Current 2022 DIM Factors for the major carriers are:

Why Is DIM weight Used?

Dimensional weight favors carriers. Prior to DIM weight, carriers priced packages solely on weight, not taking into account a package’s volume. A package’s volume is important because carriers are limited on space. For example, you could ship a 12 x 12 x 12 box of feathers and only pay a few dollars, now imagine a whole truckload of feather boxes – the carrier would lose money while transporting the feathers.

Shipping carriers are experts in maximizing space – and they want to make the most of every inch of space on their trucks. By using DIM weight, a carrier is getting a more accurate assessment of how much space is being taken up, not necessarily the weight of the package.

The Rise in Ecommerce

With the rise in eCommerce, especially in the last few years, carriers delivered more packages – taking up more capacity on trucks. Ecommerce packages are also predominantly single packages being delivered to a single residence – which is much more difficult to manage than shipping tightly packed pallets.

Ecommerce is growing and not going away like the mini-CDs of the 1990s did. Ecommerce retailers can work with their 3PLs to ensure the optimal packaging is used and by leveraging technology that provides an accurate calculated dimensional weight, so eCommerce retailers can avoid being overcharged.

Advantages of using DIM Weight

This type of pricing encourages companies to pack efficiently and reduce the amount of packaging. The advantage of DIM weight pricing goes beyond lower shipping costs and lower packaging costs, it is better for the environment in two ways – one in that the package takes less space when being transported and two in that it encourages shippers to avoid overpacking and wasting materials which will have to be thrown away.

The smaller the volume of a package, the lower your shipping costs.

There are several ways to reduce DIM weight:

- Use polybags instead of boxes when possible

- Change internal insulation with less or lighter materials

- Kitting items for one package instead of two

- Audit your shipping bills to ensure accuracy

As a Certified B Corp, AMS Fulfillment is always reviewing ways to reduce its carbon footprint. Implementing some of the changes above will go a long way to increase the bottom line while reducing the impact on the environment!

Leveraging Your 3PL to Reduce DIM Weight

How do a fulfillment company and a client come together to determine optimal packaging? The client will certainly want their product protected during shipping, and the fulfillment company will want to pack efficiently to reduce the cost for their client.

Partnering with an experienced 3PL, can make a significant impact on shipping costs. 3PLs ship a lot of packages annually and due to their sheer shipping volume, they help reduce shipping costs by negotiating better dimension denominators for the DIM weight as opposed to shipping on your own.

An advanced 3PL, like AMS, has technology that captures the exact weight and dimensions of your products. This technology enables the 3PL to determine the optimal packing strategy to reduce excess box space and shipping method for your DIM weight.

Consumer Sentiment Regarding Packaging Impact

Consumers who receive the packaging along with the product at their door, are concerned not only that their product is protected, but also about the amount of packaging that must be thrown away. We understand that the carriers have different methodologies and divisors, and the fulfillment company works with clients to keep the cost down and the package efficiently and safely done.

AMS Weighs In

We asked Chris Nocella, President of AMS East, to explain DIM weight. “From my perspective, the most critical component when it comes to DIM weight is working with clients on their packaging solutions to squeeze out as much air as possible from the finished package. Think about the last Apple product you received. It was tightly packed with very little wasted space. Each piece is properly sized, neatly stacked, and tucked in to create a package as small and efficient as possible, minimizing waste while providing a desirable customer experience.

“As a B Corporation, we look out for the environmental impact of packaging as well and we work closely with clients to advise them on packaging choices with the environment in mind.”