3PL fulfillment services is a broad term that refers to the outsourced retail and B2B order fulfillment process to a third-party logistics (3PL) provider. This includes:

When you outsource your fulfillment services to a company like AMS Fulfillment, brands leverage their expertise, technology, shipping rates, and value-added services. Fulfillment companies are strategic partners, helping brands scale, reduce overhead costs, and increase consumer satisfaction.

Both 3PL providers and fulfillment services refer to the management and shipping of products. The terms are often used interchangeably, but there are several differences to note.

The term fulfillment service refers to the basic warehousing, receiving, and fulfillment (pick, pack, and ship) of products described above. Outsourcing to a 3PL fulfillment service company is a great way for a company to start scaling and growing.

But what do companies do when they need additional supply chain services? This is where a full-service 3PL fulfillment provider can make a huge difference. A 3PL provider handles many supply chain services that a fulfillment company does not.

In addition to the fulfillment services, 3PL providers offer an array of logistics services including inventory management, warehousing and distribution, cross-docking, freight forwarding (LTL and FTL), freight consolidation and deconsolidation, and customs brokerage.

3PL providers can handle the order fulfillment services seamlessly. AMS excels at order fulfillment – boasting 99.999% order accuracy! AMS specializes in high-SKU, high-volume products including apparel, cosmetics, and nutraceuticals.

Some of the fulfillment services include:

Inventory management

Warehousing and distribution

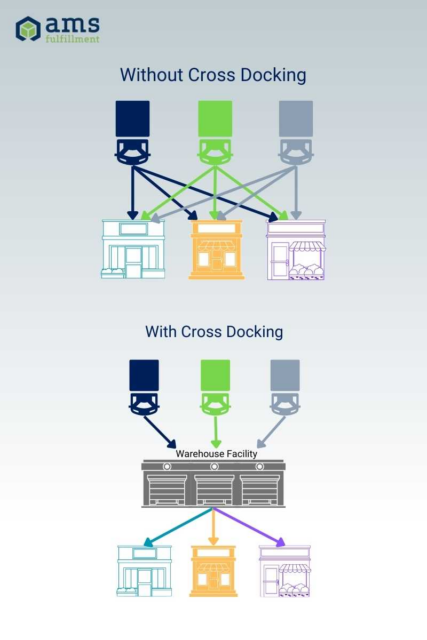

Cross-docking can be an effective and cost-saving feature. Cross-docking is when your 3PL provider receives and unloads inventory and then loads the inventory directly into outbound delivery vehicles.

Cross docking is used for a variety of reasons, but the main purpose of this fulfillment service is to reduce material handling costs and inventory storage. It is optimal to use for high-turn SKUs. Many companies use cross-docking to get their products to consumers quickly.

An example of a cross-docking fulfillment process is when Acme Company has three trucks from three different suppliers that deliver pallets of Widget A, Widget B, and Widget C. The fulfillment center then organizes the three pallets of widgets into new pallets containing all three widgets. These pallets are determined by order quantities.

Now, instead of three homogonous pallets, the fulfillment center has created pallets of mixed widgets that are ready for shipment.

While supply chain management oversees all processes and procedures related to supply chain operations, freight management only deals with the process of moving freight via a network of ships, trains, planes, and trucks to get the product from its point of origin to the end consumer. In the US, about 70% of freight is transported by trucks.

Supply chain management often involves a product’s manufacturing process as well as freight management.

Full-service third-party logistics providers offer freight management services to their clients, which end up reducing shipping costs and decreasing shipping times – so products are delivered to consumers quicker and cheaper.

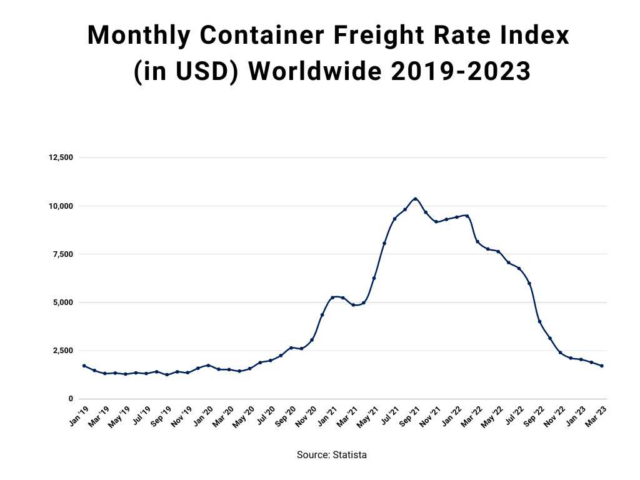

From 2019 to 2023, shipping container rates have seen record highs and lows, especially as eCommerce business demands have grown and contracted over recent years.

At AMS, we negotiate the lowest shipping rates and freight rates for online stores and brick-and-mortar stores. When our shipping rates are secured, we utilize RateLogic, a software technology platform to find the lowest shipping rates based on several factors such as package origination, destination, dimensional weight, and shipping time.

Knowing and understanding your fulfillment service needs is vital to a successful relationship with your 3PL. Knowing your short-term and long-term strategic goals is necessary when a brand is considering outsourcing to a 3PL.

There are many advantages of outsourcing to a 3PL:

As a fulfillment provider, AMS partners with you. We take the time to understand your business’s nuances and help develop the operational strategic plans you need to succeed.

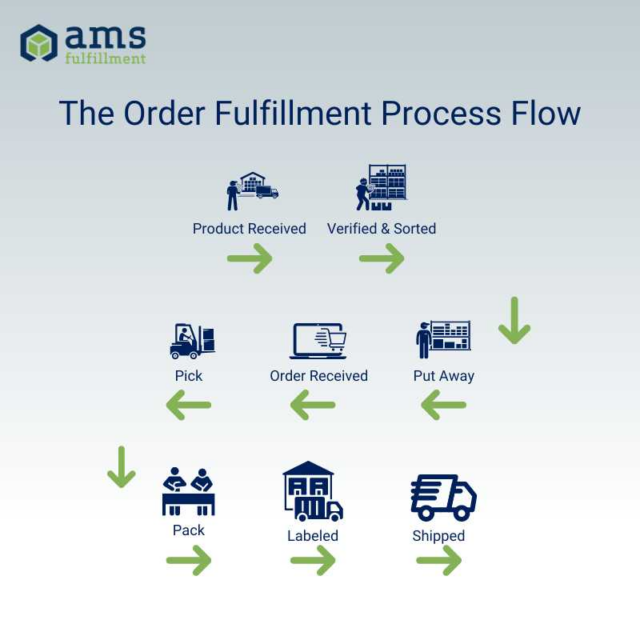

The fulfillment process has four basic activities. These are the essentials of the fulfillment process:

We have all heard the phrase “house of cards.” When you create a plan that is insubstantial, it is subject to collapse. The same goes for the inbound receiving process in order fulfillment.

Receiving inventory sounds extremely easy, however, it has several steps and each needs to be done correctly. The first step is not receiving inventory, the first step is for a company to have its SKUs set up properly in the 3PLs warehouse management system (WMS).

The 3PL will need to know how much of each SKU is expected to be received, how it is going to be received, and when it will arrive. For example, if you are shipping 10 pallets of widgets, the 3PL will need to know how many widgets are in each box and how many boxes are on a pallet.

When the inbound shipment is received, the 3PL will do a first count. This is to ensure that the number of pallets and boxes received is what was sent by the company. If everything matches the first count, the 3PL will then continue to the second count. This detailed count ensures that each box does include the correct number of SKUS.

Once the counts are done and verified, the widgets move to the next phase of receiving – the put-away process. This is where technology comes into play.

AMS’s warehouse management system, WAMS, will designate the space in the fulfillment center. The employees then put away the widgets, ensuring that all labeling is done, and systems are updated. At AMS, this is done via automation and technology to ensure accuracy.

Once the product is put away, the 3PL is ready to receive orders from your online store for B2C orders or via technology such as EDI for B2B orders.

Once the third-party logistics partner has all of the client’s SKUs verified and put away, they are ready to receive orders for picking. The picking process is often over-simplified and the fulfillment center must have the right picking strategy in place. There are several different picking strategies, but the important part is for your 3PL to have your products in the optimal location.

For example, high-volume, high-turn SKUs should be in an easily accessible location, thereby reducing pick time and worker fatigue. This is a component of inventory management. AMS ensures that these high-turn SKUs are in the optimal location, managing a client’s inventory for the quickest pick-pack process.

Technology plays a large role in inventory management and picking. At AMS, we think about where a client’s SKUs will be located well before they become clients. During the onboarding process, AMS does a thorough review of a client’s eCommerce business and fulfillment service needs. This review allows AMS to properly locate SKUs in an optimal location.

The picking process does not end with the employee taking the product off the shelf. The picking process goes through several automated verification processes. Using hand-held technology, AMS employees scan SKUs and bins to ensure that the right items and quantities have been picked. As the employees finish the fulfillment picking process, orders are brought to the packing stations.

The fulfillment process continues with the packing stage. This step is the last “hands-on” fulfillment service provided by a 3PL fulfillment company. It involves packing the order to ensure that the product is protected during the shipping stage.

Choosing the right packaging material, or dunnage is critical to preventing product breakage. There are many things to consider when selecting dunnage from durability and sustainability to shipping costs.

As a Certified B Corp, AMS Fulfillment provides fulfillment services that are sustainable. AMS is proud to provide sustainable dunnage and packing materials. We go out of our way to ensure that every step of our process as well as the materials and vendors we partner with share our sustainability goals. When it comes to a brand’s reputation and customer satisfaction, the right packing material is a major consideration. Balancing low shipping costs with properly protected products during shipping is the beginning of packing material choices.

Custom packaging includes everything from inner-carton packaging material to the actual shipping box. Fulfillment providers like AMS provide detailed services that include kitting, custom packing stations, and specialized product handling.

For online stores and eCommerce businesses, creating a cohesive, consistent brand is difficult. Often products are not in brick-and-mortar stores so consumers can’t identify the brand immediately. Branded packaging that is consistent with the consumer digital experience is a way to create brand recognition.

When selecting a third-party fulfillment company, companies need to make sure that their brand standards are adhered to – and it can start with dunnage.

One of the last order fulfillment service steps is shipping.

For this final step to be executed properly, it needs to be accurate. Ensuring shipping accuracy at this stage is set during the fulfillment center onboarding process. During the onboarding process, AMS discusses all shipping options with the client.

Over the last few years, shipping options have significantly increased. Ten years ago, shipping options included UPS, DHL, FedEx, and USPS. Today, the number of shipping carriers has exploded. Options now include international, national, and regional carriers such as GLS and OnTrac.

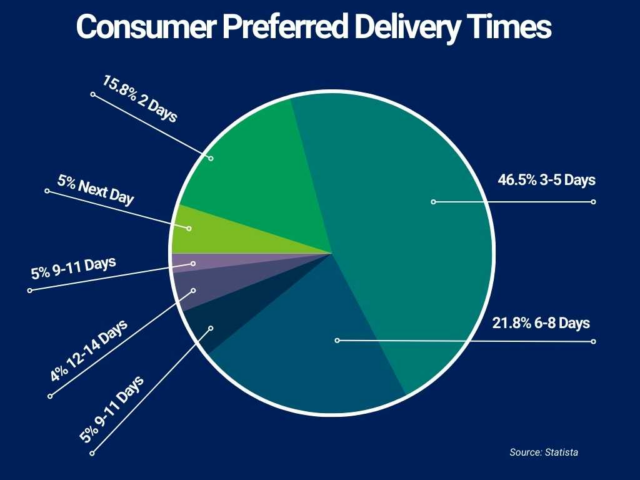

When it comes to shipping products to consumers, your fulfillment provider should be able to provide you with options from both national and regional carriers that provide the same delivery times, and often lower shipping costs. Oftentimes, this is an automated process – allowing companies to leverage all shipping options.

Shipping technology has made significant improvements over the last few years. It seems that 3PL providers have technology that “rate shops” carriers. This technology can determine the best shipping option based on consumer data as well as company shipping options (i.e. free 2-day shipping).

Based on a package’s origination location – where the 3PL is located, and where the package is going to be delivered, AMS’ RateLogic analyzes numerous shipping carriers and selects the optimal shipping method.

Many fulfillment companies offer additional services, often referred to as Value-Added Services (VAS). These can range from kitting, assembly, and labeling to industry-specific services such as hand-tagging apparel, hanger insertions, and handling garment-on-hanger (GOH).

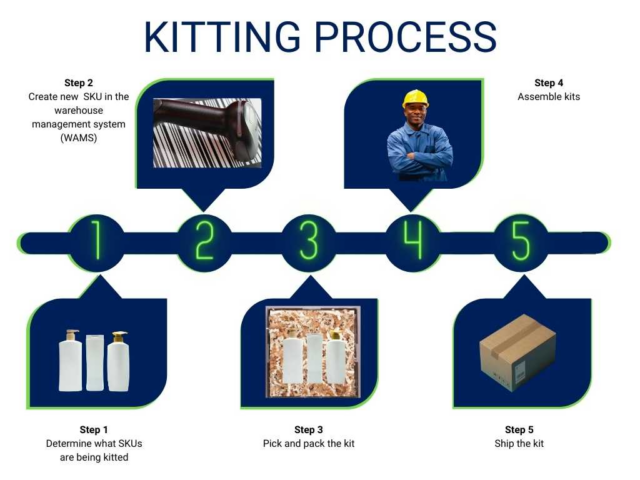

Retailers have long known the value of kitting – it can increase revenue, increase slow-moving products, and trim costs. Kitting is an inventory management technique where different SKUs are ordered, packaged, and shipped as a unit, often under a new SKU.

At AMS, we offer kitting and assembly as a fulfillment service – in fact, we excel at it.

In the warehouse, kitting involves picking multiple SKUs and “bundling” them together. A classic example of kitting is shampoo and conditioner. Often, this “kit” is bundled together via shrink wrap or other plastic wraps, glue, or in a custom box.

AMS Fulfillment specializes in high volume and high SKU counts. Our team of experienced warehouse workers is trained to handle the kitting fulfillment process quickly, efficiently, and accurately.

Kitting is often considered a value-added service or VAS, as not all brands require kitting. If a brand utilizes kitting, it is important to consider this process when evaluating fulfillment partners. Experience, accuracy, and efficiency are all important KPIs to consider during the 3PL fulfillment evaluation process.

Similar to kitting, bundling is another value-added service offered by a fulfillment provider.

The difference between a kit and a bundle all comes down to the products included. While a kit will include two or more different product SKUs, a bundle will contain two or more of the same product.

If we go back to the shampoo and conditioner kit, it is an excellent example of kitting. Sometimes a retailer or brand will want to “blow out” inventory for several reasons including discontinued SKUs or excess inventory stock. Brands can create offers like a “BOGO” or “Buy 2, Get 3” when that happens.

The shipping industry has changed over the years. It’s no wonder that labeling has evolved and changed over time too. The AMS Fulfillment team has extensive shipping and logistics knowledge so clients can be assured of having the right shipping labels no matter what country their customer lives in.

3PL fulfillment companies have hundreds of clients, each with its own routing guide and labeling requirements. The 3PL needs to have the right technology and understanding of all their clients to ensure that the right shipping label is affixed in the right location.

This is where a warehouse management system (WMS) is integral to accuracy. The WMS will have all labeling data stored and when orders are received, the shipping label will be generated with instructions for correct labeling. AMS Fulfillment’s warehouse management system is called WAMS and is powered by cutting-edge technology.

Recently, WAMS received a Type 1 SOC® report from A-LIGN – meaning that it has the controls in place that protect clients’ data.

One version of labeling is the GC1-128 Label. The GC1-128 label enables a shipping carton’s visibility throughout the entire supply chain process. This label is broken down into pre-defined zones, with each zone containing text or a barcode.

Zone 1 (the bottom zone) most commonly contains the SSCC-18 barcode which is tied to an EDI document with the carton content information.

Retail fulfillment companies have several hundreds of clients. Each client may have specific zone requirements for their trading partners. It is up to the 3PL to be able to handle all shipping label requirements unique to each of its clients.

AMS Fulfillment has robust technology that accurately and effortlessly handles all shipping label requirements.

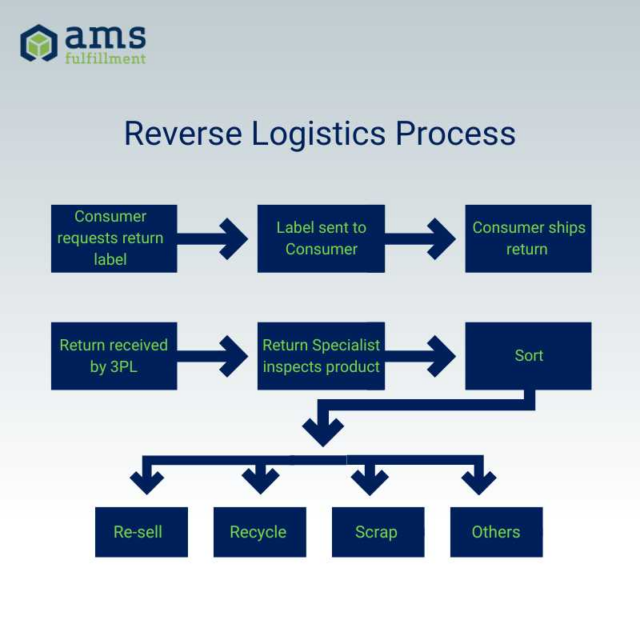

As retail sales have grown, so have returns. According to the National Retail Federation, the return rate is 16.5% in 2022. Both eCommerce returns and in-store returns account for a staggering $816.7 billion.

Working with a 3PL provider that can efficiently handle the returns management (also called reverse logistics) process is vital to ensuring the product is processed quickly and either prepped for re-sale, recycled, or scrapped.

AMS Fulfillment has dedicated returns management teams in place to handle a retailer’s returns. The Return team inspects the product and will either process the refund or authorize the refund to be processed on the retailer’s end.

Fulfillment centers have standard operating procedures in place to process returns.

Returns not only cost retailers over $603 billion but a staggering $62.1 billion of returns are also fraudulent. And it is not just retailers that are impacted by returns. In the US, states lost over $84.9 billion in retail revenue.

When these numbers are added up, it is more important than ever to ensure that valid returns are handled as quickly as possible, especially in the fashion industry, where items are seasonal and have short lifespans as trends quickly change.

It is important to have the right fulfillment partner that can handle returns, to reduce the cost of returns as much as possible.

The impact of returns on the environment is also significant. An estimated 10 billion pounds of returned products in the US end up in a landfill.

As a Certified B Corp, AMS Fulfillment is focused on sustainability. Each fulfillment center’s top priority is aimed at reducing our carbon footprint which includes handling returns.

As a full-service fulfillment provider, AMS provides many other value-added services. AMS is a true fulfillment partner and as an extension of a brand, provides the services needed for our clients to grow and scale:

Technology plays a vital role in efficient third-party logistics companies. The most important technology a 3PL could have is a warehouse management system. At AMS, the warehouse management system is WAMS, a robust, cloud-based, and flexible platform that provides real-time data. A cloud-based system enables the 3PL fulfillment partner to scale on demand – capable of handling seasonal peaks with ease.

WAMS is a top-tier warehouse fulfillment center that has passed an audit by A-Lign as a Type 1 SOC 2 for cyber security, meaning data is protected and secure.

WAMS is a proprietary WMS that is flexible to provide data and support omnichannel fulfillment, whether it is B2B, B2C, mCommerce, or social commerce. WAMS becomes part of a client’s inventory management procedures by knowing exactly how much inventory is on hand, when it’s time to reorder, or when to put items on sale for quick movement.

WAMS is constantly evolving. With an in-house development team, AMS can adapt to a client’s needs quickly and enhance the system to accommodate consumer trends, such as social commerce.

AMS clients use cutting-edge technology, enabling them to make strategic decisions and scale their businesses.

Another piece of technology that is becoming more important for retailers and brands, is rate-shopping programs. Rate shopping is a software tool that analyzes a package’s size, dimensions, and weight (dimensional weight) along with the origination and destination to determine the best shipping method for the lowest cost within acceptable delivery times.

As shipping costs continue to increase, using RateLogic, AMS’s rate shopping technology, automates the carrier selection process, saving clients time and money. This customizable rate shopping technology optimizes the shipping process for maximum efficiency and cost-effectiveness.

Technology is only an advantage if it is easy to integrate with. At AMS, clients have a dedicated, in-house IT team to support all integrations and APIs.

Integrations can vary by system, some shopping carts like Shopify, can be integrated within hours while others may take a day or so. The integration is quick and seamless and AMS thoroughly tests all integrations.

Other than the shopping cart integrations, various other systems may need to be integrated, such as a rerun platform like Returnly or Loop Returns.

As warehouse center technology improves, so does fulfillment center automation.

The rise of warehouse automation does not look like a scene from Terminator, but it has evolved to increase worker efficiency and accuracy while reducing worker fatigue. AMS utilizes several different forms of automation including put wall technology, auto baggers, and a SureSort™ system.

A put wall system is dedicated shelving that increases efficiency during the order consolidation process. Put wall systems allow 3PLs to handle a large volume of orders in a small area.

When used in conjunction with an auto bagger, put walls can handle thousands of orders in an hour. Once an order is ready to be packaged for shipping, the warehouse worker places the order items in the auto bagger, which prints the shipping label on the bag and seals it. This streamlined process decreases order processing time, resulting in orders shipping faster and ultimately improving customer satisfaction.

SureSort™ is a scalable high-speed automated sortation system. Designed for small products like cosmetics and apparel, AMS’ OPEX SureSort™ system is built with scalability in mind. Capable of handling over 2,000 orders in an hour, it has a small facility footprint, is flexible to handle multiple types of products, and is customizable to meet clients’ needs.

AMS is more than a full-service fulfillment provider. In addition to the fulfillment services, AMS can act as a client’s call center including email support and social media customer support. In addition to handling the CS aspect, AMS can provide IT support.

These additional services further reduce overhead costs, allowing clients to focus on scaling and growing their businesses.

Researching fulfillment providers is difficult. Doing a 3PL comparison is not always easy and not “apples to apples.” At AMS, we understand the 3PL fulfillment partner selection is a difficult process – and we are here to make it easier.

Before beginning the 3PL evaluation process, there are four key points to remember:

The important thing to understand in the 3PL evaluation process is that it needs to be a good fit for your company’s long-term goals. Switching fulfillment companies is an expensive process, and finding the right partner that can grow with your company is an important factor to consider.

Here is a quick list of the top questions to ask when evaluating 3PLs:

When you outsource your order fulfillment services to AMS Fulfillment, you can expect a true partnership. At AMS, we believe that when we succeed, you succeed. Contact Us today if you would like to learn more about how our fulfillment services can help with your specific needs.