When consumer products companies outsource their order fulfillment needs to a 3PL (third-party logistics company), they gain a competitive edge when it comes to supply chain management and shipping rates. The competitive edge applies to all aspects of the company – B2C and B2B order fulfillment, inventory management, and shipping costs.

Outsourcing fulfillment to a third-party logistics provider is partnering with logistics and supply chain experts. This is a critical aspect of any business. By outsourcing, you can focus on marketing, growth, and customer satisfaction.

So “what is 3PL shipping“? A 3PL order fulfillment company stores your inventory. They pick, pack, and ship your products. They also ensure quick picks, inventory, and shipping accuracy. Knowing when your order fulfillment center runs smoothly is easy. Your customers are happy, your reviews are excellent, and your business is growing. All of this adds up to success.

Of all the advantages of outsourcing to an expert order fulfillment company like AMS Fulfillment, 3PL shipping rates may be the most significant. For example, companies with high margins, say 50%, can afford to spend 15% of order revenue on shipping. Companies with low margins have significantly less to spend on shipping. No matter your revenue margin, expect to pay 15-20% of it on shipping.

3PL shipping rates are negotiated with the carriers and are based on volume (the number of total shipments). The higher the volume, the lower the shipping rates.

In a recent article, Lee Spratt, CEO of DHL eCommerce Solutions America said “Retailer’s top priority is lowering shipping costs, with speed a close second.”

When companies outsource their order fulfillment and shipping to a third-party logistics provider, they receive lower shipping rates immediately. This could be a significant contributor to customer satisfaction. By being able to offer faster shipping at the same or lower rates to customers, companies are primed for growth!

What Is a 3PL?

A 3PL provider is part of the supply chain process. They handle inbound receiving, picking and packing, shipping, warehousing, and many logistic functions such as cross-docking and freight management.

A 3PL is often called an order fulfillment company or order fulfillment center. Although the terms are used interchangeably, there is a difference between a 3PL and an order fulfillment center. Companies like AMS Fulfillment are full-service order fulfillment centers, providing all the 3PL services in addition to several fulfillment services including:

- Warehousing

- Return management

- Kitting/bundling/assembly

- Labeling

- Routing Requirements

- EDI routing compliance

- Inventory management

- Picking and packing

- Shipping and receiving

- Various industry-specific value-added services

-

- Hand-tagging apparel

- Hanger insertions

- Garment-on-hanger (GOH)

Additional services offered by some 3PL providers include:

- FTL and LTL freight shipping.

- Freight forwarding

- Kitting

- Reverse logistics (returns)

How Do 3PLs & Order Fulfillment Centers Work?

Both order fulfillment centers and 3PLs provide companies with essential logistics operations functions – pick, pack, and ship.

When outsourcing your order fulfillment, your overhead costs are significantly reduced – you don’t own the warehouse, hire the staff, or manage operations. These overhead costs are part of the third-party logistics company.

The warehouse receives your products (inbound) and places them into inventory. When orders are received, whether it is a B2B or a B2C (DTC) order, the items are picked from shelves to fill orders and packed securely for shipping.

The 3PL or order fulfillment center works with various carriers to deliver orders to your clients.

An experienced order fulfillment center such as AMS Fulfillment has warehouses that are optimized for maximum speed and efficiency. As you scale your business, the increased order volume is easily handled by the fulfillment center.

How to Reduce Shipping Costs

In addition to lower overhead costs, a 3PL will work with you to get lower shipping rates and fast delivery times. A 3PL employs supply chain professionals with extensive knowledge and experience.

Lowering shipping costs can have a significant impact on revenue. By reducing shipping rates, you can reinvest funds into product development, marketing, and technology.

When you think of reducing shipping costs, the first thing that comes to mind is the shipping rate. Did you know that packaging should be one of the first places to review?

Optimal Packaging = Lower Shipping Costs

Packaging is an important component in the supply chain. Packaging is considered to be a coordinated system of preparing products for safe and efficient movement through the entire supply chain, up to and including the consumer unboxing experience.

The role of packaging in supply chain management has a significant impact on shipping costs.

There are major considerations when selecting packaging.

- Durability

- Regulatory considerations

- Eco-friendly/Sustainability

- Consumer experience

- Size – Dimensional weight

Durability

We have all received shipments where a box is crushed or broken. When that ruined box arrives on our doorsteps, we immediately expect damaged or destroyed products, especially if what we ordered contained fragile products like glass.

Shipping packaging needs to be strong enough to withstand the shipping process. Packaging serves to protect your products both during the shipping process and while it is being warehoused.

For your outer packaging, it is important to select the most durable packaging. Packaging needs are vastly different between an apparel company and an essential oil company. While the apparel company can utilize polybags, the essential oil company will not only need durable boxes, but inner carton packaging (dunnage) such as molded pulp packaging, air pillows, or foam.

Selecting the lightest and most durable packaging will go a long way to reducing shipping costs.

Regulatory Considerations

Many regulated or HazMat products have specialized packaging requirements to be shipped. According to US Code Title 49, hazardous shipments not prepared properly cannot be transported by air, highway, rail, or water. The Code further states that “It is the duty of each person who offers hazardous materials for transportation to instruct each of his officers, agents, and employees having any responsibility for preparing hazardous materials for shipment as to applicable regulations in this subchapter.”

At AMS, our fully trained, specialized staff handles all hazmat product warehousing and shipping requirements.

Some of the regulatory considerations include inner packaging limits, packaging materials, as well as markings, and any potential additional documentation.

If you have regulated products such as lithium batteries or perfume, partnering with an order fulfillment center with regulatory compliance experience is a must.

Sustainable Packaging

Sustainable or Green packaging refers to the shipping and packaging materials that are reusable, biodegradable, or compostable. It also refers to the manufacturing techniques and recycling properties of the material.

According to Statista, in 2019, the estimated market value of green packaging was $178.6 billion, that number is expected to increase to $246.3 billion in 2025. This expected growth is directly attributed to consumer demand as well as corporate initiatives.

Consumers are demanding sustainable packaging – in a recent Ad Age article, 82% of consumers would pay higher prices for products sold in sustainable packaging, which is up 4% from 2022.

As a Certified B Corporation, AMS Fulfillment provides sustainable packaging solutions to all of our customers.

Dimensional Weight

Of all the packaging considerations, dimensional weight (dim weight) has one of the biggest impacts on shipping costs. Dimensional weight is a volume metric used by all carriers to determine package costs.

When you outsource to an order fulfillment center or 3PL, they will review “optimal packaging” for your products. These supply chain experts will review packaging options such as polybags, boxes, dunnage (packaging materials), and package size.

Dim weight is the cubic feet a package takes up on a truck or container. Shipping carriers determine their pricing based on this metric, which they call dim weight pricing.

If you are shipping dog toys in a 10”x10”x10” box you would pay for a 7-pound package even if the dog toys weighed less than a pound. If the pet products were able to fit into a 5”x5”x5”, you would only pay for two pounds. This is a significant savings for retailers.

Dimensional weight affects every aspect of supply chain management. By using the right-sized packaging, you can reduce shipping costs from the onset. When packaging is too big, these boxes need to be stabilized with dunnage, which is often in the form of air pillows or cushioning.

Third-Party Logistics Integrations

3PLs and order fulfillment centers are supply chain technology experts – at least they should be! Brands and retailers are no longer only available “in-store” or “online”. Multi-channel and omnichannel selling are mandatory for today’s consumers.

Omnichannel is a unified consumer experience. It involves all channels for sales and marketing including online sales (brand website), big-box retailers, digital marketplaces like Amazon, as well as social selling and mobile applications. The goal of a brand is to have a cohesive, consistent selection of products available wherever the consumer is at that moment in time.

While omnichannel selling is a cohesive experience, multi-channel selling is ensuring your products are available on all shopping platforms including online, social, and in brick-and-mortar stores. It also means that you need your online store to be available on desktops and mobile devices.

Two of the most important aspects of omnichannel selling are shopping cart integration and inventory management.

eCommerce sales rely on shopping cart integrations – such as Shopify or BigCommerce. When your third-party logistics provider integrates with your shopping cart, it integrates your shopping cart with the warehouse management system (WAMS).

When integrating with a client’s shopping cart, AMS establishes a direct API connection to your shopping cart store, allowing us to pull orders, push shipping data, and also sync inventory quantities between WAMS and your shopping cart.

The result of the direct integration is real-time data and analytics – giving you control over your business no matter what channel you are selling on.

Technology plays a huge role in 3PL shipping – and you need a partner that has a reliable, secure, and trustworthy order fulfillment platform. At AMS, we took the extra step to ensure that WAMS is the top-tier warehouse management system. Recently, WAMS passed A-Lign’s Type 2 SOC Audit. This accomplishment means that WAMS meets strict data integrity and security.

Inventory management is complex, especially as a company grows and adds new SKUs. Many order fulfillment centers are not capable of handling high SKU counts. At AMS, we excel at handling high SKUs, thanks in part to our robust warehouse management and inventory management systems.

If you have a high SKU count – what do you need to look for in a third-party logistics provider?

- Technology-driven cycle count programs with full physical inventories.

- Syncing of inventory data between warehouse management systems and your shopping carts.

- Security and accuracy for your valuable products.

- 3PL warehouse layout that drives efficient pick and pack operations.

Technology is the backbone of any order fulfillment center. It needs to be supported by experienced and knowledgeable staff. At AMS, we have our own US-based IT department ready to support all your sales needs – from Brick-and-mortar stores to online sales!

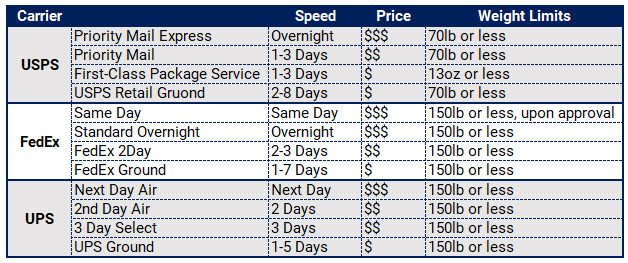

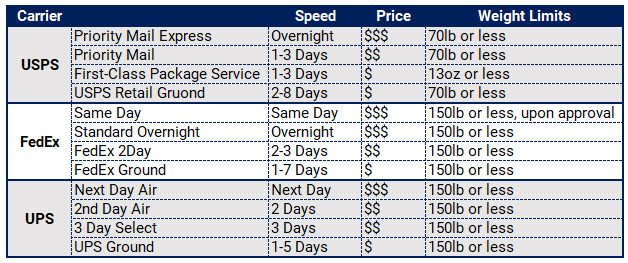

Types of Fulfillment Shipping Services

Third-party logistics providers and order fulfillment centers both offer several shipping options from a variety of shipping carriers. Determining the right shipping options for your business can be overwhelming to many companies.

Once again, 3PLs have a huge technological advantage when it comes to shipping costs.

RateLogic

On the forefront of rate shopping platforms, AMS has a proprietary system, RateLogic, that analyzes all carrier shipping contracts and determines the lowest cost option with the desired shipping time. By automating this process, AMS ensures the best possible shipping costs for its clients.

AMS’ team can customize RateLogic’s rules based on a client’s supply chain shipping needs.

When automating the shipping selection process with RateLogic, AMS ensures that our clients save time and money, while streamlining shipping operations. RateLogic optimizes the shipping process for maximum supply chain efficiency and cost-effectiveness.

Consumer Demand and Shipping Options

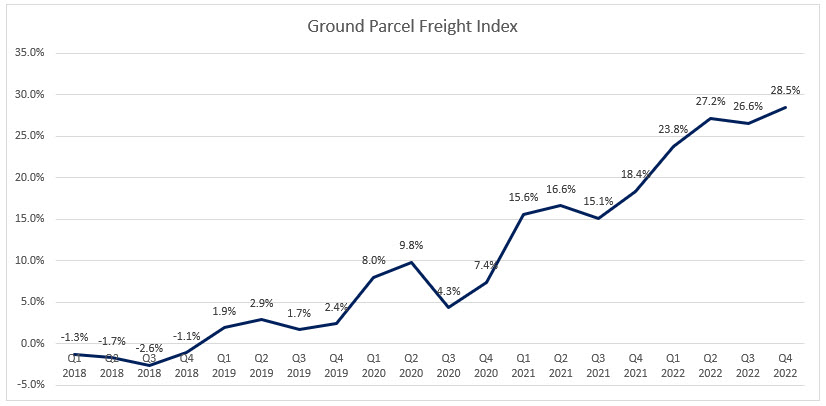

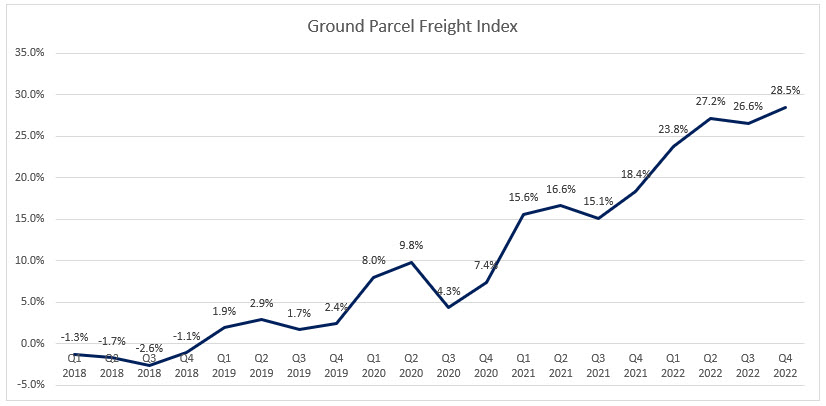

Consumers are demanding quicker delivery times. In 2019, consumers expected their packages to be delivered in 4.3 days. That number decreased to 3.5 days in 2022. Meanwhile, shipping carriers have significantly increased rates.

Shipping Times

Balancing shipping costs with shipping times is a constant conundrum for retailers. The main carriers, USPS, UPS, and FedEx, all offer similar shipping times. So, it simply should be a matter of selecting your preferred shipping carrier or the carrier with the lowest shipping costs.

In addition to the legacy carriers (FedEx, USPS, and UPS), the rise of regional carriers like OnTrac, Lasership, and Spee-dee Delivery, have greatly increased the shipping options available to companies. Although the carrier space has gotten more competitive, shipping costs continue to rise due to inflation, prior supply chain issues, and increased consumer demand.

Balancing your shipping costs with shipping times is a difficult task, but one that needs to be done to remain profitable and competitive.

Drop Shipping & Order Fulfillment Centers

A drop shipping eCommerce business model is different from a traditional business model. Instead of having your product on hand at your order fulfillment center, dropshipping is an eCommerce business model where you list products online but purchase inventory after customers make purchases.

There is little to no upfront capital investment with drop shipping. In addition, you will not have to pay warehousing and storage costs. On the flip side, the drop-shipping model has smaller profit margins since you will pay a higher wholesale price for your products.

How Does Drop Shipping Work?

Drop shipping is an easy business model to implement.

- Sign an agreement with a wholesaler, manufacturer, or other retailer to provide the goods it advertises.

- Once the agreement is in place and your website is up and running, customers can place their orders.

- When you receive an order, this triggers two actions:

- Send an order confirmation to the customer.

- Forward the order to the wholesaler, manufacturer, or other retailer.

- That company ships the order.

- If you are working with an order fulfillment provider, coordinate shipping and inbound receiving between the 3PL and wholesaler.

- Inventory is received by the 3PL, and the order fulfillment process begins (pick, pack, ship).

- 3PL ships the orders.

- The customer receives their product.

Can Your Order Fulfillment Center Handle Drop-shipping?

Order fulfillment centers and 3PLs excel at handling drop shipping! Daniel Butera, COO at AMS Fulfillment explains how AMS handles drop shipping.

“A drop shipper is no different than any other eCommerce client. There are 2 models: Model 1 is the flash sale model. This means that the order fulfillment center does not warehouse any inventory. The client posts a sale on their website or other flash sale platforms. They then sell the goods. Finally, they place the order with the manufacturers.

“The manufacturers send us the goods as well as the order file, and we ship accordingly. In this model, they can send us the order either before the goods arrive, or after.”

“For the second model,” Butera continues. “We hold all the inventory, and the client sells against what we are holding. This is the standard eCommerce model. When clients generally talk about drop shipping, they are referring to selling items either on Amazon, Nordstrom, or any other eCommerce site. In those cases, either the retailer or the client transmits the orders to us to fulfill them direct to the end customer. AMS then processes the orders as a standard eCommerce order, along with any specific packing or labeling requirements the retailers need.”

By using a third-party logistics provider, drop shippers can save on shipping costs just like other omnichannel companies.

Are You Ready to Outsource Your Order Fulfillment?

Before you outsource your order fulfillment to a third-party logistics provider, you should do an internal review of your company’s strategic goals, scalability options, and expected return on investment (ROI).

We hear it so many times, you started your company as a side gig or hobby years ago, but it has grown into a real thing! Congratulations! You made it past the crucial first years as a business owner!

Now you no longer have the warehouse space, labor, or technology to fulfill orders as quickly as your customers demand and your shipping costs have skyrocketed.

Here are signs that you are ready to outsource your shipping to a 3PL:

1. You Struggle to Keep up With Order Volume

Not that long ago, you got your first small warehouse and were self-fulfilling your orders – you and your family! That expanded to hiring full-time employees, renting a larger space, and hiring more workers. The daily order volume has taken off but unfortunately, so have your overhead costs.

As order volume increases, storage, staffing, and technology need to keep up – and that requires funds that may not be readily available since they are tied up paying for higher shipping costs.

Outsourcing to an order fulfillment center eases many costs including overhead, infrastructure, technology, and shipping costs. 3PLs and order fulfillment centers split the total infrastructure and overhead costs between all of their clients, significantly reducing your costs.

And when it comes to shipping costs, the 3PL will have much lower rates based on volume.

2. Your Customers Are Demanding Faster Shipping Times

Consumers want fast delivery and manual order fulfillment takes time – precious time. One advantage of outsourcing your order fulfillment to a 3PL is automation. Top-tier fulfillment centers like AMS have invested in automation like pick-walls and box assembly, which streamline their order fulfillment process. And faster fulfillment means your products are shipped faster!

And when it comes to shipping – location matters. Fulfillment centers with multiple, bi-coastal facilities reduce shipping times and costs. If you promise 2-day shipping to your customers, you need to deliver on it. If your product is warehoused in Atlanta, GA and your customer is in Seattle, WA, you can expect to pay for the costly air shipping methods. However, if you have bi-coastal facilities, you can fulfill the order from your West Coast facility and thereby decreasing the shipping times and reducing shipping costs.

3. Shipping Costs Are Eating Away at Your Profit Margin

Shipping costs continue to rise. Legacy carriers (i.e., FedEx and UPS) raise their shipping rates annually; the last increase was 6.9%. With these rising costs, shipping is cutting profit margins everywhere.

Getting orders to customers’ doorsteps quickly is expensive. Because a 3PL negotiates shipping rates with carriers based on package volume, outsourcing to a 3PL is an excellent option to take advantage of their lower shipping rates.

4. Your Inventory Management isn’t the Greatest

Inventory management is an integral part of the supply chain management process. Inventory management is the process of ordering, storing, and selling your products. On the surface, it sounds relatively simple, but inventory management isn’t that simple.

Fulfillment centers are optimization experts. They know how warehouses should be laid out to maximize the pick, pack, and ship processes. They understand product seasonality and high SKU turns. Fulfillment centers continuously optimize their warehouses for the quickest fulfillment process.

But inventory management isn’t just about location and optimization. Inventory data needs to be organized so you know when to order products, when to have “flash” or “last chance” sales, discontinue products, or perhaps do some kitting and bundling to move products.

Outsourcing to a 3PL will provide you with a robust warehouse management system that shows in real-time your inventory levels, analyzes your inventory turns, and much more. You will have complete control over your inventory and streamline your procurement process.

5. Customer Service Is Lacking

An often-overlooked part of the order fulfillment process is customer service. When your customers are not receiving their orders on time, orders arrive incorrectly, or when returns are not posted quickly, customers often call your customer service department or worse – take to social media.

Did you know that $75 billion dollars is lost due to poor customer service? Even worse, 96% of customers will switch to a competitor if you have poor customer service.

These statistics are sobering.

A 3PL can help ensure accurate order fulfillment. They use technology to check that product, quantity, and address details match. This results in an accuracy rate of 99.998%.

Outsourcing to a full-service order fulfillment center like AMS gives businesses the option of supplementing their customer service team. AMS can provide additional support and resources to ensure customer satisfaction. Yes, you can outsource part of your CS functions to your 3PL.

For example, you can outsource all your return processing customer service functions to AMS, so your customer service team can focus on other customer questions.

Advantages of Outsourcing Fulfillment Services

In 1999, there was a commencement speech that became well-known – Sunscreen. One of the lines in the speech was “Accept certain inalienable truths/prices will rise…”

And costs have gone up everywhere – shipping costs, supply chain costs, product costs, labor costs, and warehouse costs!

Outsourcing your fulfillment to a 3PL or order fulfillment center is a smart business strategy to reduce all those costs while giving companies back the most elusive commodity – time.

Growing a business takes time and resources. By outsourcing to a fulfillment center, time that was spent on order processing, supply chain management, and inventory management, can now be focused on efforts that will grow your business, like marketing, sales, and research and development.

When you outsource to AMS Fulfillment, you are partnering with a reputable, top-tier, full-service order fulfillment center and B Corporation. Not only are you partnering with a company that values people over profit and is committed to “doing good” for people, communities, and the environment, you are partnering with a company that takes pride in being the operational extension of your company.

Your success, your profit margin, and your growth matter to AMS. Contact Us today and see how we can help!