Reverse logistics is the process of bringing goods back from consumers and is considered an inbound logistics activity. Consumers have product returns for several reasons including defects, wrong sizes, and wrong items shipped. Reverse logistics is a tedious and expensive process, costing retailers over $4.4 billion in 2021.

Reverse logistics is the process of bringing goods back from consumers and is considered an inbound logistics activity. Consumers have product returns for several reasons including defects, wrong sizes, and wrong items shipped. Reverse logistics is a tedious and expensive process, costing retailers over $4.4 billion in 2021.

Can outsourcing returns save retailers money?

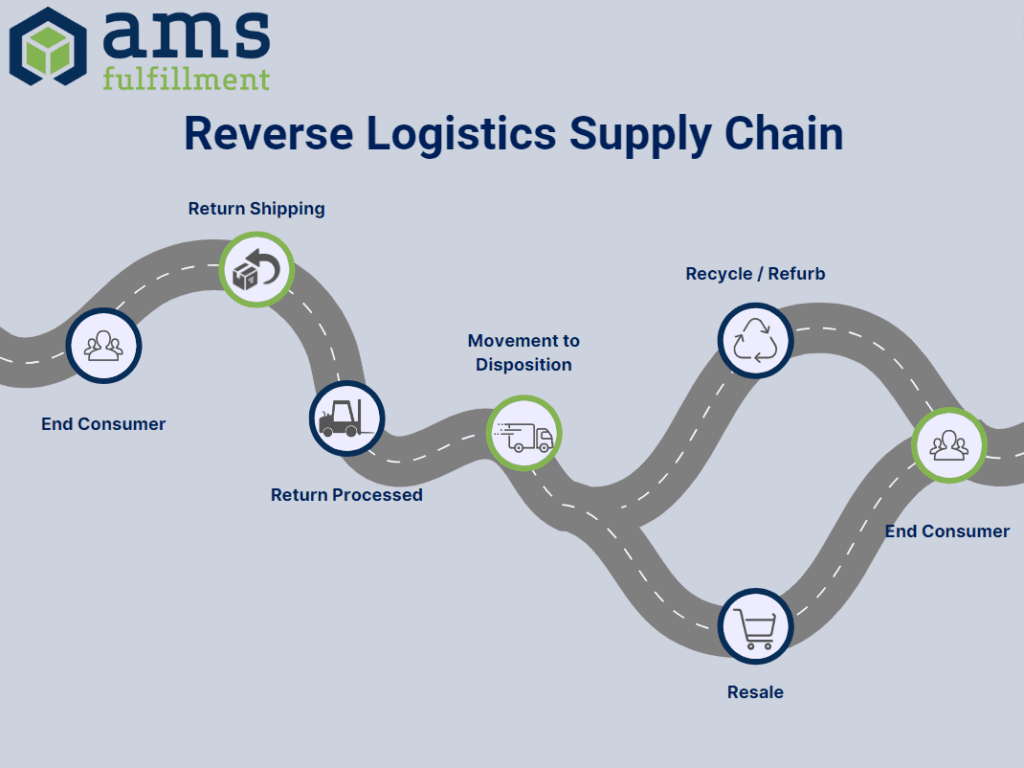

Before we talk about outsourcing eCommerce returns and refurbishment, we’ll need to understand reverse logistics. The question can be answered simply by the five “R’s”: Returns, Reselling, Repairs, Repackaging, and Recycling.

A very good explanation of what makes up reverse logistics is offered by c3controls: “Reverse logistics comprises of the sector of supply chains that process anything returning or coming in from a procurement source inward through the supply chain or traveling ‘backward’ through the supply chain. Hence the name reverse logistics.”

According to The Council of Logistics Management, we’re talking about the process of implementing, controlling, and planning the cost-effective flow of finished goods, raw materials, and in-process inventory. “The flow is from the point of consumption (i.e., the customer) to the point of origin (i.e., the manufacturer), to properly dispose of these or to recapture value.”

Supply Chain Crisis – Can’t Take Product In

The fulfillment industry is dealing with a supply chain crisis that started in late 2019 and continues. With the supply chain under pressure, the term inbound logistics indicating reverse logistics has gained more steam and it continues to broaden. Although it has been an under-optimized area, with the pressures on the supply chain it has become vital for companies to focus on inbound (reverse) logistics.

In fact, inbound has become more important than outbound. If we cannot get inventory in, we certainly can’t get it out no matter the circumstances of why inventory is flowing in a backward, inbound, or reverse direction. It is most critical to keep inventory levels at pace with demand.

Reverse logistics is critical for any business selling merchandise of any type, including industries we serve like beauty fulfillment, cosmetics fulfillment, and more. This most critical, and often most neglected, part of the supply chain must be constantly managed, monitored, and maintained within any organization. Is a business wise to outsource this process, what can be gained by outsourcing?

First, this area of logistics should not be neglected. Reverse logistics provides invaluable data that is crucial to correcting existing issues that might be causing the return of products. Secondly, proper management of materials traveling back up the supply chain can reduce losses and add revenue by refurbishing, repairing, and recycling or selling products or materials from the goods.

Outsourcing for Cost Savings

Outsourcing can reduce the costs of reverse logistics by streamlining the processes, which are often spread over multiple sections of the supply chain. Again, this can encompass anything from returned goods, inbound merchandise or raw materials, recycling of packaging materials, responsible disposal of materials from previously sold products, and much more.

Retailers can see a return on investment quickly. Some areas of savings include:

- Reduced labor overhead costs

- Less warehouse space

- Less equipment and utility expenses

- Increased profits

Customer retention and enhanced levels of brand image are perhaps the most important reason to outsource your company’s reverse logistics. Your customers and your brand matter! In competitive markets, proper Returns Processing is vital.

Returns are a reality for many of AMS Fulfillment’s clients. We help streamline returns through our dedicated Returns Management team. We employ a great crew, automated systems, and client-specific processes that help minimize the costs associated with returns handling; and quickly get inventory back onto the shelf as shippable finished goods (for those items that can be refurbished).

With the rapid build-up of external pressures, it may be time to consider outsourcing. We invite you to contact AMS Fulfillment. As a B Corporation, you also can be sure that we always do right by our stakeholders, the community, and the environment.

** ** **

About the Author: John Bevacqua is the creator of the “Freight Freak” monthly blog, and former VP of Logistics at AMS Fulfillment. He currently serves, in semi-retirement, as Logistics Advisor.