“At AMS, we stress the importance of knowing how to evacuate safely and quickly during an emergency. In the past, when we have a practice drill, we noticed employees walking all the way across the warehouse to an employee exit. In a real emergency, we let employees know that they should exit at the closest door. Remember, it’s an emergency and employee safety comes first. Calmly walk out at any door and walk around the building. Find where other employees are gathering. This will be your evacuation point. Make sure that you check in and give your name. In an emergency/natural disaster, we tend to naturally think of our families and want to get home. If an employee does not check in, we will start searching for them inside a warehouse when it’s safe to go in. We would rather know that our employees have safely evacuated.”

Matt also shared with us one of the training materials, prepared by Eric Wiseman, on how to approach fire safety.

*Fires ravage 28,000 industrial facilities each year, causing $596 million in direct property damage. Ninety percent of these fires can be attributed to human errors. Fires can be prevented with an awareness of the hazards and safe work practices. These include: good housekeeping practices, proper procedures when handling flammable material, what to do if a fire breaks out, and the proper use of fire extinguishers.

*A fire needs three elements to exist: oxygen, heat and fuel. Fuel is anything that will burn when exposed to heat. It can be a solid, liquid or gas. Fuel sources include paper, wood, oil, grease, chemicals, and flammable liquids.

*The leading heat sources that could cause these fuel sources to burn include electricity, cigarettes, cutting and welding, sparks from tools, and friction.

*Good housekeeping can help you to separate the heat sources from fuel sources. Flammable liquids are used so often in the work environment that they are often taken for granted. Liquids, themselves, do not burn, but they form vapors that do burn.

*Flashpoint is the lowest temperature at which the vapor from combustible liquid can be made to ignite. The lower the flashpoint, the more dangerous the liquid.

*Flammable Range is the volume of vapor needed in the air for a fire to start if it needs a heat source. It is measured in percentages.

*Spontaneous Combustion occurs when a flammable liquid catches on fire without an outside heat source, such as a spark or a cigarette. The temperature at which this occurs is called the Ignition Temperature.

*Fire extinguishers are classified according to the type of fire they are effective against. The type of fuel that a fire is composed of determines it classification. When using a fire extinguisher remember the acronym P.A.S.S.

Pull the pin.

Aim low, at the base of the fire.

Squeeze the handle to release the extinguisher agent.

Sweep from side to side to keep the fire from spreading.

*Follow the practiced evacuation plan. Exit the building quickly. Do not duck and cover like Earthquake evacuation. Go to the designated meeting area. Find your supervisor so they can check you off their roll call.

*Do NOT FOR ANY REASON RE-ENTER THE BUILDING.

Leave the work to the professionals. Stay out of Fire Department’s way.

Matt also offered the following with regard to heat safety:

“Heat exhaustion – At AMS, our warehouses are sometimes just as hot inside as they are outside. We encourage employees to drink plenty of liquids. Every warehouse has water dispensers and employees can refill their water bottles as much as they’d like. Our receiving teams are unloading trucks that are extremely hot. Sometimes 20 -30 degrees hotter than it is outside. We make sure that those employees are switching roles periodically. We stress the importance of “See Something, Say Something”. If you are feeling dehydrated, speak up. If you see a co-worker with signs of exhaustion or dehydration, say something immediately. A little prevention goes a long way.”

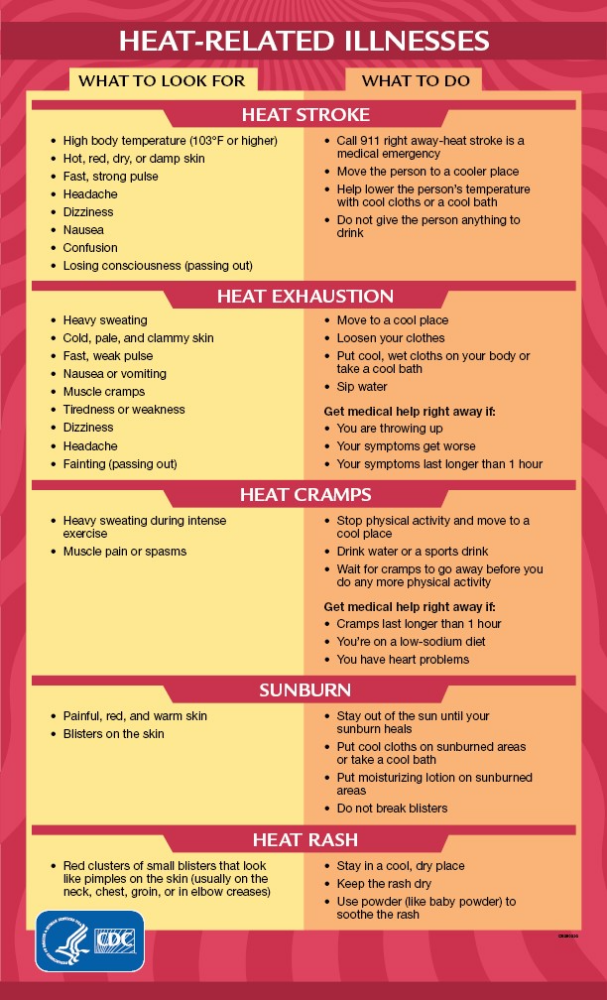

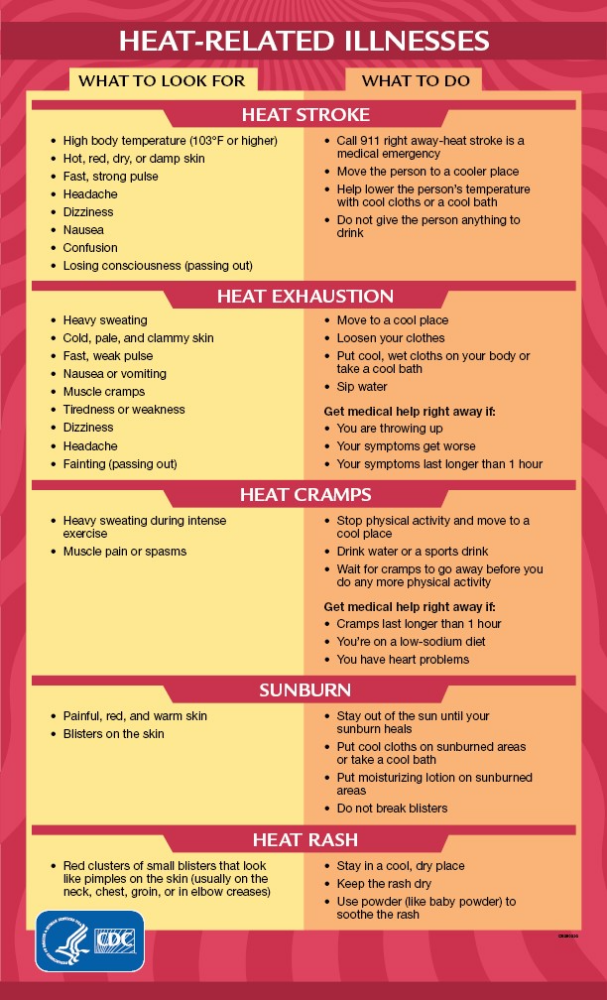

Please review the chart below that shows what the signs of heat exhaustion are, and what to do in case of such an emergency.

Thank you to Matt and Eric for this valuable information.